Our New Machines

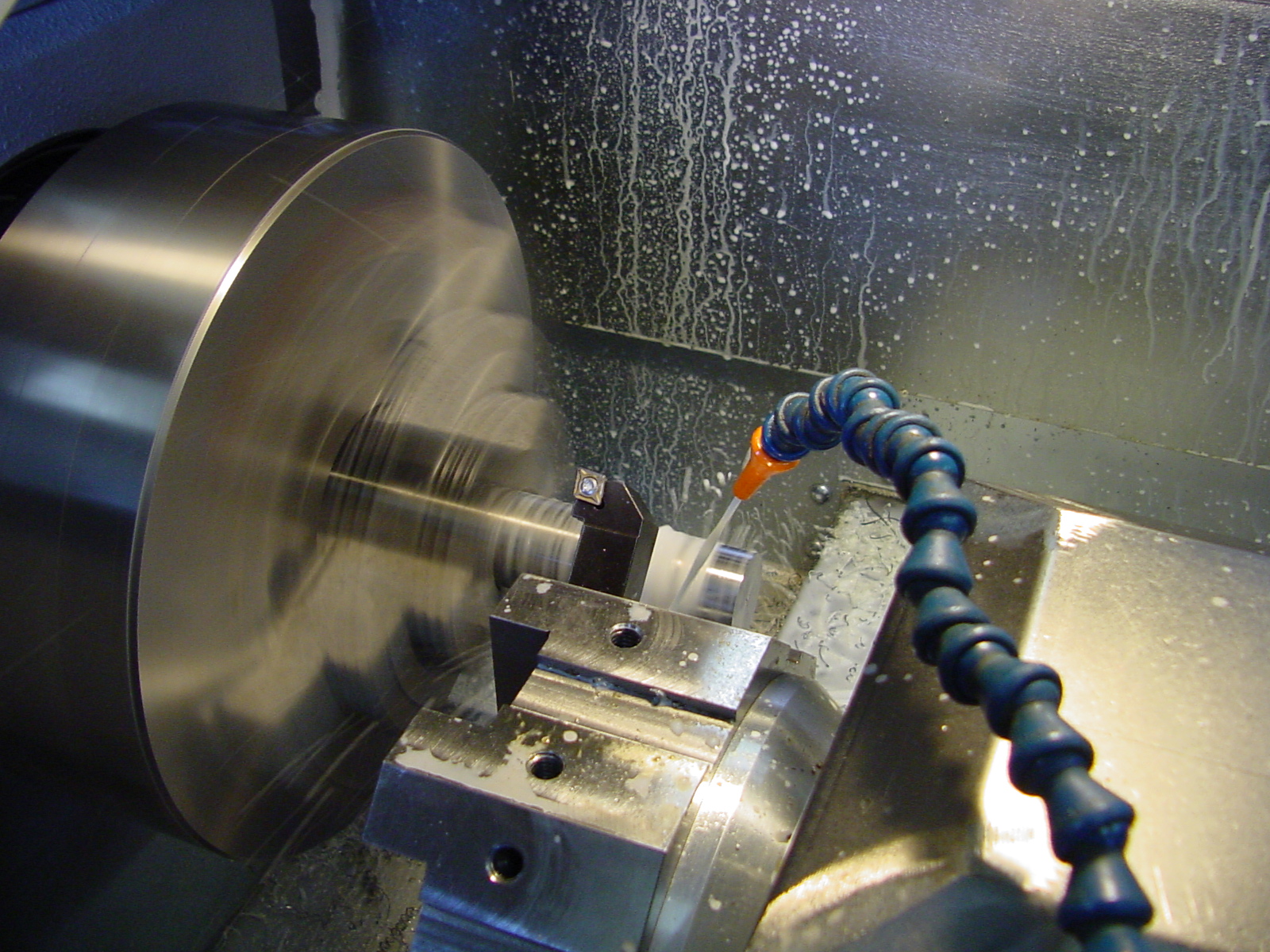

Our Machines utilize Renishaw probe solutions which can help reduce set‑up times by up to 90% and improve process control (tool setting, broken tool detection, component set-up, in-cycle gauging and first-off component inspection, with automatic offset updates).

Haas VF2 SS (Super –Speed) 2016 with a new controller (4 axes ready)

Super-Speed Vertical Machining Center; 30″ x 16″ x 20″ (762 x 406 x 508 mm), 40 taper, 30 hp (22.4 kW) vector drive, 12,000 rpm, inline direct-drive, high-speed 24+1 side-mount tool changer, 1400 ipm (35.6 m/min) rapids, power-failure detection module, 1 GB program memory, 15″ color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 55-gallon (208 liter) flood coolant system.

[/et_pb_text][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid”]Haas VF2 SS (Super –Speed) 2014 (4 axes ready)

Super-Speed Vertical Machining Center; 30″ x 16″ x 20″ (762 x 406 x 508 mm), 40 taper, 30 hp (22.4 kW) vector drive, 12,000 rpm, inline direct-drive, high-speed 24+1 side-mount tool changer, 1400 ipm (35.6 m/min) rapids, power-failure detection module, 1 GB program memory, 15″ color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 55-gallon (208 liter) flood coolant system.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]